Biocoal from Forest Waste

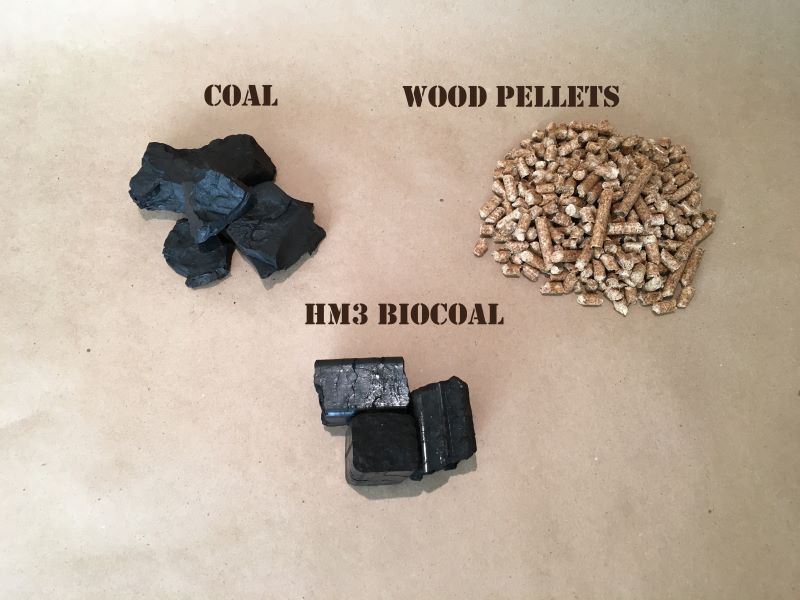

HM3 Energy produces biocoal (also known as black pellets) from forest waste and other biomass. HM3 Energy’s patented technology is so energy-efficient and cost-effective, its HM3BiocoalTM is cheaper than white pellets as drop-in coal replacement fuel at the burner tip.

Carbon Neutral – HM3BiocoalTM is carbon neutral fuel that produces no mercury or sulfur emissions.

High Btu Content – HM3BiocoalTM has the same energy as coal and 30% more than white pellets.

Water Resistant – Shipping and storage costs are substantially reduced compared to white pellets.

Grinds like Coal – White pellets are fibrous and require substantial modifications to the coal plant feeding system. HM3BiocoalTM feeds just the way coal does.

No Binders – No additional chemicals are added during production of HM3BiocoalTM that can impact the boiler during combustion.

With this advance in torrefaction technology, we predict biocoal (black pellets) will replace white pellets as coal replacement fuel and fuel for new biomass power plants.

Biocoal from Forest Waste Can Reduce Wildfire Risk

Critical thinning operations performed in the forest to restore it to a healthier state helps the forest become more resilient to catastrophic wildfire. Without an end user, the biomass resulting from these thinning operations is typically piled up in huge slash piles and burned. HM3’s technology makes biocoal (black pellets) from the forest waste.

Coal Replacement Fuel

Carbon neutral HM3BiocoalTM works as drop-in coal replacement fuel to extend the lives of existing powder coal plants. It also provides a more environmentally friendly and superior alternative to the white pellets for the export market for use in both coal-fired and biomass-fired power plants.

Proven Technology

Three years of continuous testing and process improvements in a $4.4 million demonstration facility have resulted in the most energy-efficient and cost-effective way to produce biocoal (black pellets).

Superior Biocoal

Not all biocoal is the same. HM3BiocoalTM is demonstrably cheaper to produce than other biocoal. In fact, it beats white pellets in cost ($/Gigajoule) at the powder (pulverized) coal plant burner tip.

Hardgrove Grindability

GJ / Metric Ton

Btu / Pound

2nd Generation Biomass Energy

With recent technological advances, biocoal is poised to become the biomass energy of choice. HM3 Energy is licensing its environmentally friendly, commercially viable biocoal from forest waste technology.